As the electronics industry continues navigating the aftermath of the pandemic, a notable shift is underway in inventory management practices. According to industry expert Brian Doherty, interviewed by Evertiq, the sector is transitioning from a reactive phase—characterized by supply chain disruptions—to a more balanced approach to supply and demand. While some segments still grapple with overcapacity, others are experiencing normalization. However, Doherty cautions that this balance remains fragile, with potential risks that could lead to renewed shortages.

Doherty highlights that customers are currently reducing their inventory levels and that macroeconomic uncertainties are prompting cautious forecasts. He expresses concern that if tariff uncertainties ease and demand increases, suppliers may struggle to respond quickly enough, possibly leading to a resurgence of what he terms a “scarcity mentality.” This could destabilize the industry’s hard-won equilibrium.

Changing Customer Expectations

Over recent years, the disruptions faced have fundamentally altered customer expectations from distributors. Doherty emphasizes that today’s customers seek more than just availability—they demand predictability, transparency, and speed in supply chain operations. This shift has driven a movement towards localized sourcing and diversified supply chains, aimed at mitigating risks associated with the global supply chain.

However, Doherty raises the critical question of whether customers are willing to accept higher costs in exchange for increased resilience. Notably, he points out that the industry’s previous focus on securing the lowest purchase costs often led to reliance on single-site processing to maximize efficiency. Now, the industry must adapt to meet evolving customer demands for enhanced service without inflating costs unnecessarily.

To address these shifts, distributors like DigiKey are enhancing their logistics capabilities and developing tools that improve inventory visibility and lead times. The expectations for technical information have also evolved; customers now look for additional data, such as country-of-origin details, tariff flags, and carbon footprints, beyond conventional datasheets and product images.

Key Forces Shaping Future Growth

Doherty identifies three significant forces that will define the next growth phase of the electronics industry:

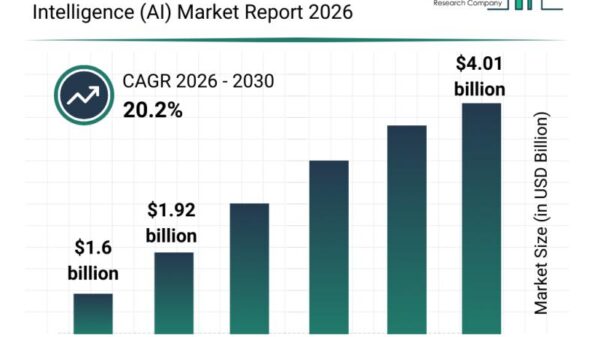

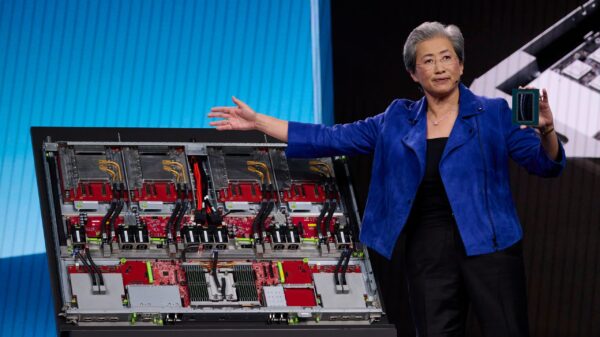

- AI and Automation: Historically, high service levels have been associated with high costs. However, customers are now prepared to pay for value rather than inefficiencies. The integration of AI across the value chain is set to transform operational efficiency.

- Geographic Rebalancing of Manufacturing: While Asia continues to dominate, North America and Europe are simultaneously ramping up efforts in reshoring and nearshoring, fostering regional manufacturing strategies.

- Sustainability and Compliance: As customers increasingly demand traceability and ethical sourcing, DigiKey is positioning itself at the forefront of AI adoption, global logistics, and environmental, social, and governance (ESG) transparency.

The Role of AI at DigiKey

DigiKey is actively integrating AI to streamline its operations. Doherty explains that AI is enhancing processes such as quoting, inventory optimization, and customer responsiveness. For instance, the company employs AI tools to parse Excel attachments in emails, which expedites and increases the accuracy of quotes.

Furthermore, predictive analytics play a vital role in demand forecasting and in minimizing excess inventory, enabling DigiKey to remain both lean and reliable. Doherty elaborates, stating that AI support encompasses predictive systems that anticipate demand shifts and customer-facing tools that improve the overall buying experience. The company is also exploring the use of generative AI to enhance internal processes, including request intakes through conversational agents that facilitate detailed business case development.

As AI continues to reshape the distributor-customer relationship from transactional to collaborative, engineers are leveraging AI-driven design tools to simulate components pre-purchase. Procurement teams are increasingly dependent on intelligent platforms to assess risk and automate routine tasks. DigiKey is preparing for this evolution by developing user-friendly interfaces, including chatbots and smart search tools, to enhance customer engagement.

The electronics supply chain, having moved beyond a state of emergency, is yet to settle into a stable pattern. The upcoming phase of industry development will depend heavily on AI adoption, regional manufacturing adjustments, and heightened demands for transparency. The distributors that can blend operational speed with resilience and invest in future-defining tools and infrastructure will likely emerge as the victors in this evolving landscape.

See also Sundar Pichai Warns AI Models Can Make Mistakes, Urges Caution in Blind Trust

Sundar Pichai Warns AI Models Can Make Mistakes, Urges Caution in Blind Trust Google Launches Gemini 3 with Enhanced Coding, Integrated into Search Engine

Google Launches Gemini 3 with Enhanced Coding, Integrated into Search Engine Nvidia Invests $24B in AI, Sparking Investor Concerns Over Circular Deals

Nvidia Invests $24B in AI, Sparking Investor Concerns Over Circular Deals EU Launches Investigations into Amazon and Microsoft as Potential Cloud Gatekeepers

EU Launches Investigations into Amazon and Microsoft as Potential Cloud Gatekeepers OpenAI’s GPT-5 Update Sparks Controversy Among AI Relationship Users and Community Reactions

OpenAI’s GPT-5 Update Sparks Controversy Among AI Relationship Users and Community Reactions