Researchers have developed a methodology for classifying bamboo density, utilizing advanced deep learning techniques on samples of Moso bamboo sourced from Anji County in Zhejiang Province, China. The study, which adhered to local and international guidelines, involved processing the bamboo to a standard air-dried state with controlled moisture content, ensuring optimal conditions for accurate analysis.

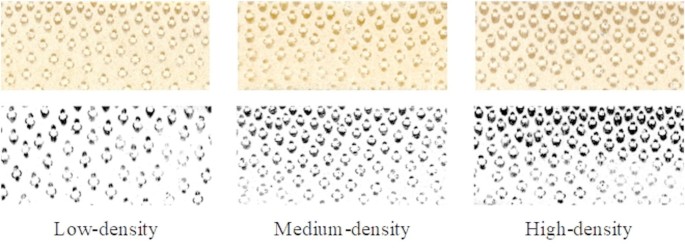

The bamboo strips, measuring approximately 20 cm in length and free from defects, were cut into segments of 3.5 cm known as short bamboo strips. In order to establish a reliable baseline for their experiments, the research team measured the volume of semi-finished bamboo toothbrush handles using the drainage method, resulting in an approximate volume of 9.0 cm³. Subsequently, the bamboo was categorized into three density classifications—low, medium, and high—according to stringent factory product quality requirements.

A total of 410 sample images were captured using a high-resolution scanner, with the dataset reflecting the density classifications outlined earlier. This resulted in 125 low-density, 116 medium-density, and 169 high-density samples, formatted according to the COCO dataset standard. The images served as the foundation for training several deep learning models to classify bamboo density effectively.

Employing a robust experimental setup, the team utilized the PyTorch framework on an Intel Xeon Silver 4410T CPU paired with an NVIDIA GeForce GTX 4090 GPU. This configuration enabled the processing of various classification models that included ConvNeXt, DenseNet, EfficientNet, MobileNet, and the Vision Transformer, among others. The objective was to analyze performance across these models, examining their strengths and weaknesses in bamboo density classification, ultimately providing insights for future applications.

Integral to the preprocessing pipeline was a sequence of image enhancements designed to optimize the clarity of the bamboo cross-sections. The original color images were converted to grayscale, followed by the application of Contrast Limited Adaptive Histogram Equalization (CLAHE) to improve local contrast. A Gaussian blur was then employed to reduce noise, which could obscure critical details. Contour extraction utilized an adaptive Canny edge detection algorithm, ensuring accurate outline identification of the target cross-section.

Evaluation metrics for the models included Precision, Recall, and the F1-score, balancing the trade-offs between true positives, false positives, and negatives. These metrics provided a comprehensive view of each model’s classification capabilities, with results indicating varying degrees of performance across the different architectures tested.

As the research progresses, findings are anticipated to provide valuable contributions to the field of bamboo product manufacturing, particularly in the development of bamboo toothbrush handles. The insights gained from this study may guide future innovations in sustainable materials, as the demand for environmentally friendly products continues to rise.

See also AI Research Submissions Surge 200% in 2025, Raising Urgent Novelty Concerns

AI Research Submissions Surge 200% in 2025, Raising Urgent Novelty Concerns AI Systems Projected to Consume Up to 765 Billion Litres of Water Annually, Surpassing Bottled Water Use

AI Systems Projected to Consume Up to 765 Billion Litres of Water Annually, Surpassing Bottled Water Use AI Research in Cardiovascular Disease Surges 400% Since 2018, Reveals Key Trends and Insights

AI Research in Cardiovascular Disease Surges 400% Since 2018, Reveals Key Trends and Insights IIT Delhi’s AILA AI Runs Complex Lab Experiments Independently, Reducing Time by 90%

IIT Delhi’s AILA AI Runs Complex Lab Experiments Independently, Reducing Time by 90% AI Study Maps 100 Years of Aging Research, Reveals Key Trends and Gaps

AI Study Maps 100 Years of Aging Research, Reveals Key Trends and Gaps