Artificial Intelligence (AI) is often touted as a transformative force in various sectors, yet a significant portion of AI initiatives face challenges. The Project Management Institute indicates that 70-80% of AI projects do not succeed. Despite this, there’s a notable shift toward embracing industrial AI applications, particularly in manufacturing and other labor-intensive fields. This article explores the critical advancements and challenges associated with industrial AI deployment.

While buzz around generative AI tools like ChatGPT, Gemini, and Claude mainly pervades office environments, the real revolution is occurring in factories, construction sites, and power plants. According to a Reuters/Siemens report, around 20% of global organizations have already adopted industrial AI for applications such as energy management and predictive maintenance. Furthermore, over 60% of businesses are either implementing or planning to implement such systems within the next three years, with objectives ranging from supply chain optimization to real-time operational decision-making.

TechUK highlights that successful AI implementations could significantly benefit the UK economy, projecting a contribution of £550 billion by 2035. IFS, an Enterprise Resource Planning (ERP) specialist, describes this emerging trend as an “invisible revolution” capable of revitalizing global manufacturing. Their research indicates only 32% of global businesses have effectively integrated AI into workflows, but nearly 60% anticipate doing so within a year. The percentage of companies merely “experimenting” with AI is expected to plummet from 24% to 7%.

Industrial AI: Bridging the Gap

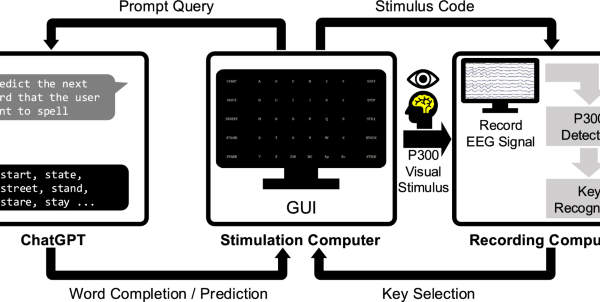

IFS Chief Product Officer Christian Pederson emphasizes that industrial AI is crucial for companies reliant on physical assets. “You have 30% of the workforce behind a desk, while 70% are out there getting their hands dirty,” he explains, noting that much of the discourse surrounding AI overlooks this crucial distinction. Industrial AI focuses on automating and optimizing business processes to enhance decision-making and productivity, requiring vast data collection from sources like IoT sensors, cameras, and back-office systems.

According to IFS, 57% of organizations surveyed in the UK are utilizing automation AI, while 46% employ predictive AI, and 37% have adopted agentic AI solutions. For instance, a company providing hygiene services transformed its field service operations by leveraging AI algorithms for scheduling and routing, achieving a remarkable 40% increase in technician productivity. “You can then decide what to do with that increased productivity,” Pederson notes, highlighting the flexible outcomes of such advancements.

Another noteworthy success story comes from TOMRA, a recycling giant that enhances its operations using anomaly detection algorithms. By analyzing data from its machines, TOMRA improved its first-time fix rate for engineers from 84% to an impressive 97%. Pederson remarks that the implementation of an “agentic dispatcher” autonomously manages technician schedules and optimizes routing, which could soon extend to guiding robots as well.

Challenges Ahead for Industrial AI

Despite the promising prospects, the journey to successful industrial AI implementation is fraught with challenges. A striking 91% of UK organizations reported improved profitability due to AI, and 95% believe it positively impacts the environment. However, leveraging AI effectively necessitates high-quality, clean data. A study indicates that 26% of businesses in the UK and US experienced data poisoning attacks last year.

Legacy systems and skill gaps present significant hurdles. Over half of organizations surveyed by IFS predict that up to 60% of their workforce will require retraining for AI tools, with a third estimating that 100% may need to adapt. This retraining effort often clashes with a cultural resistance from employees who fear job displacement. “The biggest challenge is not the technology, it’s the change management,” states Pederson.

As organizations strive to address these issues, they must recognize the vital role humans play in AI deployment, particularly in safety-critical environments. Usman Ikhlaq, AI program manager at techUK, emphasizes the importance of ensuring human oversight in these processes. He expresses optimism that organizations can navigate challenges surrounding data quality, security, and skills upgrade.

With robust cybersecurity measures, strong data governance, and strategic alignment of AI initiatives, companies can unlock transformative capabilities. TechUK’s recent Industrial Strategy aims to prioritize frontier technologies, including AI, as essential to economic growth. However, companies that hesitate to adopt AI risk falling behind in an increasingly competitive landscape.

See also Abidur Chowdhury, iPhone Air Designer, Joins Unnamed AI Startup Amid Talent Exodus at Apple

Abidur Chowdhury, iPhone Air Designer, Joins Unnamed AI Startup Amid Talent Exodus at Apple Cassava Technologies and Rockefeller Foundation Expand AI Access to 8 African Nations

Cassava Technologies and Rockefeller Foundation Expand AI Access to 8 African Nations Microsoft Launches Project Gecko to Deliver Customizable AI for Low-Resource Languages

Microsoft Launches Project Gecko to Deliver Customizable AI for Low-Resource Languages AI’s Role in Climate Action Sparks Controversy at COP30 Talks in Brazil

AI’s Role in Climate Action Sparks Controversy at COP30 Talks in Brazil Andrometa Launches YapWorld, Pioneering the “Social AI” Sector to Combat Digital Isolation

Andrometa Launches YapWorld, Pioneering the “Social AI” Sector to Combat Digital Isolation