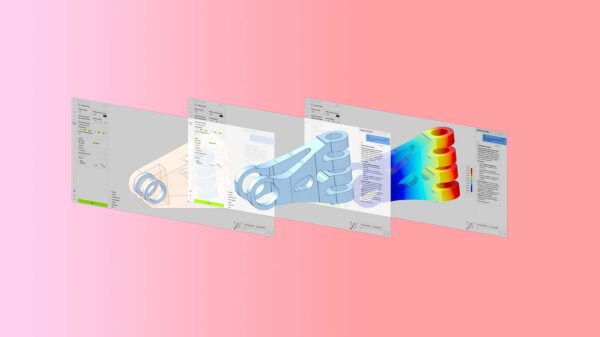

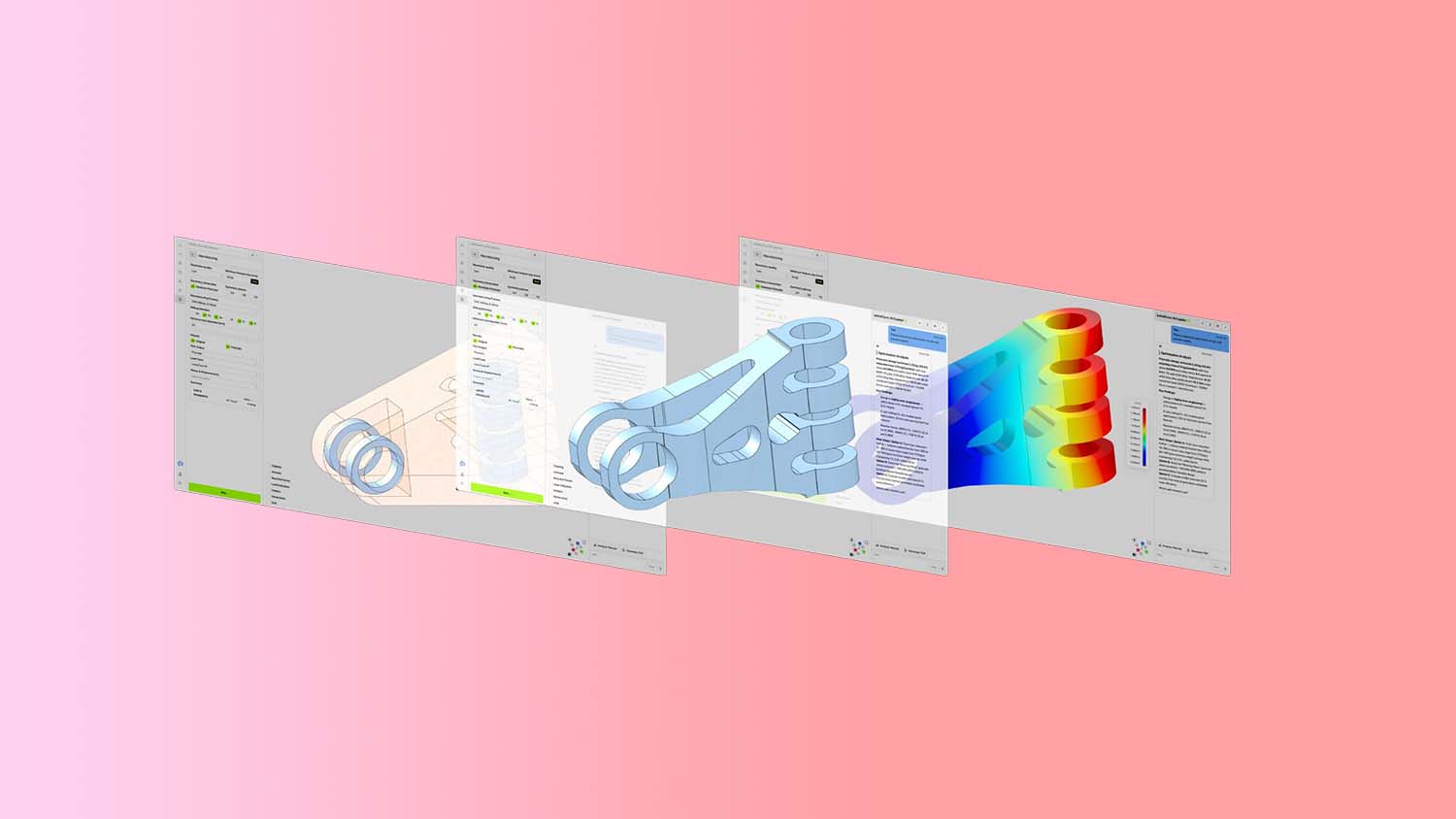

InfinitForm has introduced its Generative Engineering Platform, designed to enhance part design optimization for traditional manufacturing processes, effectively addressing the longstanding gap between design and manufacturing. The launch aims to streamline workflows and improve efficiency in an industry often hindered by silos between design and production.

The platform automates the analysis of various manufacturability variables, such as wall thickness, draft angles, tool size, accessibility, tolerance stack-up, assembly complexity, and tooling feasibility. This comprehensive approach enables optimization for multiple manufacturing processes, including CNC machining, die casting, injection molding, extrusion, additive manufacturing, and hybrid manufacturing.

By integrating proprietary, GPU-accelerated solvers with InfinitForm’s AI Co-Pilot, engineers can automate design for manufacturing (DFM) analysis while focusing on performance and cost efficiency. This technological advancement dramatically reduces manufacturing timelines from “weeks to days,” as AI-optimized outputs minimize revision cycles and enhance first-pass yields.

Dr. Michael Bogomolny, CEO of InfinitForm, remarked, “Design and manufacturing have long operated in silos, creating inefficiencies and costly delays. While traditional generative design tools were intended to bridge this gap, they largely optimize for additive manufacturing and ignore the constraints of most production methods.” He emphasized that the new platform combines design optimization with manufacturing intelligence, ensuring engineers no longer face a choice between performance and manufacturability.

The Generative Engineering Platform is tailored for prismatic engineering designs. To further facilitate customer workflows, InfinitForm has partnered with Autodesk Fusion and Siemens NX, in addition to being a Research Associate with Dassault Systèmes Solidworks. This collaboration allows for the provision of parametric designs with full design history integrated into those CAD systems.

In describing the platform’s capabilities, Bogomolny stated, “Our goal is to empower engineers with AI design and engineering tools that unlock innovation and new efficiencies rather than replace their expertise.” He added that the manufacturing-first platform enhances engineering knowledge, accelerates DFM processes, and enables engineers to concentrate on creative design rather than manual iterations.

Another critical aspect of the Generative Engineering Platform is its Privacy-First Architecture, which safeguards intellectual property. Customer designs are excluded from the training data for the platform’s algorithms, ensuring that proprietary data remains protected at all times.

For those interested in evaluating the platform, DEVELOP3D readers can sign up for a 30-day trial of the InfinitForm Generative Engineering Platform. This initiative reflects a broader trend in the technology sector, where companies increasingly leverage AI to enhance productivity while addressing the challenges of traditional manufacturing workflows.

As industries evolve, the integration of advanced technologies like AI into design and manufacturing processes is expected to redefine operational efficiencies, allowing engineers to innovate and reduce time-to-market for new products.

See also Tesseract Launches Site Manager and PRISM Vision Badge for Job Site Clarity

Tesseract Launches Site Manager and PRISM Vision Badge for Job Site Clarity Affordable Android Smartwatches That Offer Great Value and Features

Affordable Android Smartwatches That Offer Great Value and Features Russia”s AIDOL Robot Stumbles During Debut in Moscow

Russia”s AIDOL Robot Stumbles During Debut in Moscow AI Technology Revolutionizes Meat Processing at Cargill Slaughterhouse

AI Technology Revolutionizes Meat Processing at Cargill Slaughterhouse Seagate Unveils Exos 4U100: 3.2PB AI-Ready Storage with Advanced HAMR Tech

Seagate Unveils Exos 4U100: 3.2PB AI-Ready Storage with Advanced HAMR Tech