As global supply chains grapple with unprecedented challenges, business leaders are increasingly turning to artificial intelligence (AI) and emerging technologies to bolster resilience and efficiency. Issues such as labor shortages, rising costs, and geopolitical disruptions have laid bare the vulnerabilities of traditional supply chain models, prompting a shift toward more sophisticated operational strategies.

While AI has garnered significant attention, its most impactful applications are emerging from a hybrid model where human decision-makers collaborate with AI systems. This approach enables organizations to make smarter, faster decisions regarding the design and optimization of their supply chain networks.

In the United States, the modern supply chain has become a complex ecosystem fraught with challenges. Leaders are navigating an aging labor pool, inflationary wage pressures, volatile tariffs, and heightened expectations for e-commerce fulfillment speed. As a result, supply chain leaders are re-evaluating their operational structures and strategies.

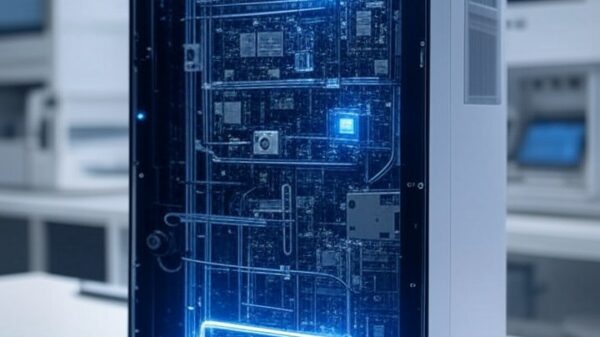

Simultaneously, advancements in automation technology—from robotic picking systems to autonomous forklifts—have expanded the available toolkit. However, this technological abundance has also introduced uncertainties, forcing supply chain leaders to discern which solutions will yield a genuine return on investment (ROI) while aligning with overarching strategic goals.

In this context, AI is transitioning from an experimental tool to an essential asset for supply chain management. Rather than solely automating tasks, AI can assess, model, simulate, and continuously optimize entire supply chain networks. This capability helps leaders understand not just what to automate, but where and why such automation should occur.

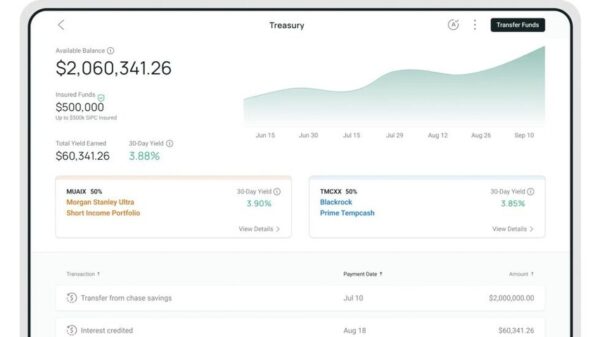

The role of AI in supply chains begins with data, capturing every movement of goods and orders. However, many organizations still face challenges with incomplete or siloed datasets. Advanced simulation and “digital twin” modeling are emerging as vital tools to bridge these gaps. By creating a virtual replica of operations, supply chain leaders can explore various “what-if” scenarios before making real-world investments. For instance, they can evaluate the impact of a demand spike in a specific region or assess how a new distribution center might affect transport costs.

These simulations not only predict outcomes but also generate high-quality datasets that feed into machine-learning models, enabling AI to identify optimal network configurations. Over time, the system becomes increasingly intelligent, refining decision-making through continuous learning.

Despite AI’s capabilities, the human perspective remains irreplaceable. Practitioners who have navigated the complexities of supply chain operations possess insights—such as the impact of supplier delays or the nuances of warehouse layouts—that algorithms alone cannot grasp. In this hybrid model, AI serves as a force multiplier, enhancing the capabilities of demand planners and network designers.

To successfully integrate AI into supply chain operations, organizations should evaluate opportunities through four interconnected lenses: operational, technical, strategic, and commercial. Each lens assesses different facets of potential automation, helping leaders identify solutions that not only meet day-to-day needs but also align with broader business objectives.

For executives contemplating AI integration, a structured approach is crucial. They should begin by asking the right questions about the challenges they aim to address, such as cost-to-serve, speed, or resilience. Following this, organizations need to assess and prepare their data, ensuring that even imperfect datasets can yield valuable insights through simulation.

Building a digital twin allows companies to model their current networks and use AI to explore alternative configurations, assessing various locations and levels of automation. Once optimal scenarios are generated, they should be validated with human expertise and stakeholder input. Continuous iteration and improvement will ensure that the network adapts to evolving market conditions.

Looking ahead, the next frontier in supply chain AI involves real-time network optimization. As Internet of Things (IoT) sensors, robotics, and edge computing technologies mature, supply chains will increasingly be able to self-adjust in response to live data, enhancing their resilience against disruptions. Ethical considerations surrounding AI governance will also become critical, ensuring that transparency and human oversight remain integral to these systems.

As AI continues to reshape the landscape of supply chain management, organizations that effectively combine digital capabilities with operational insight will likely emerge as leaders in the field. Rather than replacing human decision-makers, AI aims to empower them with enhanced visibility, foresight, and adaptability, ultimately laying the groundwork for resilient and future-ready supply chains.

In an era marked by constant disruption, embracing hybrid intelligence in supply chain operations may not just offer a competitive edge, but is becoming essential for crafting optimized and resilient network structures.

IBM | Microsoft | Nvidia | OpenAI | Amazon | DeepMind

See also Perplexity Launches Comet AI Browser for Android, Enhancing Mobile Web Navigation

Perplexity Launches Comet AI Browser for Android, Enhancing Mobile Web Navigation Samsung Elevates 161 Executives in Bold AI Push, Targeting Chip and Software Dominance

Samsung Elevates 161 Executives in Bold AI Push, Targeting Chip and Software Dominance Nvidia Set to Surpass $20 Trillion Valuation as AI Infrastructure Demand Soars 360% by 2030

Nvidia Set to Surpass $20 Trillion Valuation as AI Infrastructure Demand Soars 360% by 2030 OpenAI Reveals Prototype for AI Device, Set to Launch in Under 2 Years, Jony Ive Confirms

OpenAI Reveals Prototype for AI Device, Set to Launch in Under 2 Years, Jony Ive Confirms HP to Lay Off Up to 6,000 Employees by 2028 as AI Restructuring Cuts Costs by $1B

HP to Lay Off Up to 6,000 Employees by 2028 as AI Restructuring Cuts Costs by $1B