Johannes-Keppler-Universität Linz is embarking on an ambitious research initiative focused on machine learning and signal processing within the steelmaking sector, in collaboration with voestalpine Stahl. The project will be conducted at the University’s Christian Doppler Laboratory for Signal Processing and Machine Learning in the Steel Industry (CD) and is set to continue until 2032. Funded by Austria’s Federal Ministry of Economy, Energy and Tourism, the initiative has received an endowment of €2.7 million (approximately $3.2 million).

The laboratory aims to advance theoretical principles and develop algorithms intended to enhance signal processing capabilities for monitoring steel manufacturing processes. Project leader Oliver Lang emphasized the critical role of sensors that capture various signals during production processes, such as those employed by voestalpine Stahl GmbH. “Production processes are monitored by sensors whose signals are processed by specialized algorithms,” Lang explained. He pointed out that among the types of signals encountered, approximate periodic signals stand out as a focal point of the research.

Lang noted that despite their frequent occurrence, there has been limited research on approximate periodic signals, resulting in a scarcity of effective algorithms for their processing. Such signals are particularly prevalent in strip mills, where continuous operations lead to a range of rotations and oscillations. “These almost periodic signals create a multitude of critical interfering signals,” he added, highlighting the challenges posed by these phenomena.

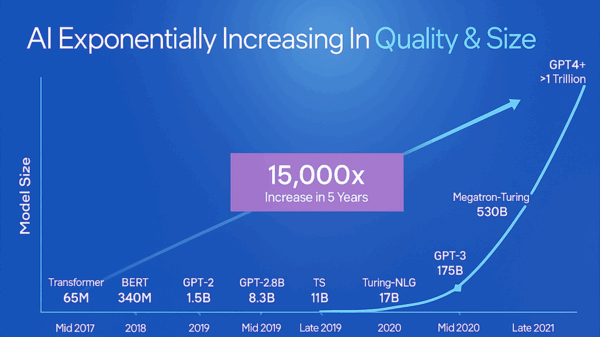

The intent of this research initiative is not merely to address existing challenges but to pioneer advancements in the processing and interpretation of these complex signals, thereby improving the overall efficiency and reliability of steel manufacturing. The collaboration signifies a substantial investment in technology that could have far-reaching implications for the steel industry, particularly as it increasingly integrates advanced data analytics and machine learning techniques.

As the project unfolds, it is expected to provide valuable insights that can lead to more refined monitoring and control in steel production processes. By leveraging machine learning techniques, the initiative aims to mitigate the impact of noise and interference in signal processing, ultimately enhancing product quality and operational efficiency.

This partnership between academia and industry not only underscores the importance of interdisciplinary collaboration but also reflects a growing trend in the manufacturing sector toward the adoption of cutting-edge technologies. As the steel industry faces growing demands for efficiency and sustainability, initiatives like this may play a crucial role in its evolution.

Looking ahead, the outcomes of this research could serve as a cornerstone for future innovations in steelmaking, potentially influencing a broader spectrum of manufacturing processes. The ongoing integration of machine learning and advanced signal processing is set to redefine traditional practices, enabling the sector to meet the challenges of an increasingly complex industrial landscape.

See also Stanford AI Tool Predicts 130 Diseases from One Night of Sleep with 80% Accuracy

Stanford AI Tool Predicts 130 Diseases from One Night of Sleep with 80% Accuracy FactSet Expands AI Integration, Projects $2.4B Revenue by 2026 Amid Rising Tech Costs

FactSet Expands AI Integration, Projects $2.4B Revenue by 2026 Amid Rising Tech Costs AI Study Reveals Generated Faces Indistinguishable from Real Photos, Erodes Trust in Visual Media

AI Study Reveals Generated Faces Indistinguishable from Real Photos, Erodes Trust in Visual Media Gen AI Revolutionizes Market Research, Transforming $140B Industry Dynamics

Gen AI Revolutionizes Market Research, Transforming $140B Industry Dynamics Researchers Unlock Light-Based AI Operations for Significant Energy Efficiency Gains

Researchers Unlock Light-Based AI Operations for Significant Energy Efficiency Gains