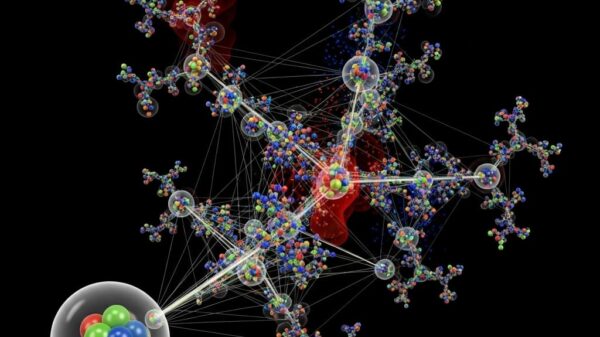

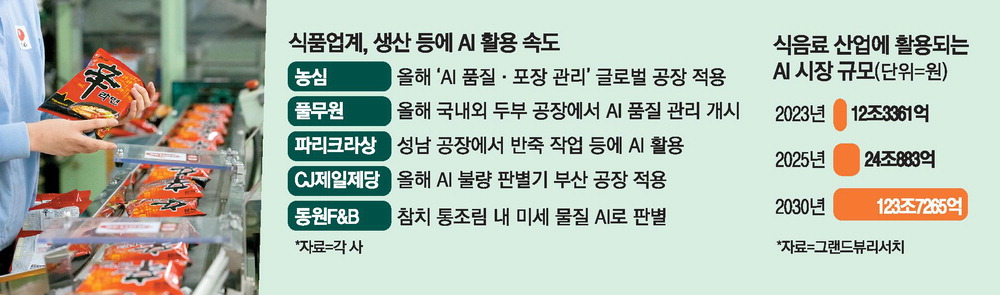

Nongshim, the leading entity in the ramen industry, has announced plans to expand its artificial intelligence (AI) product discriminator, a technology previously used only in domestic factories, to overseas production lines in the United States and China this year. This innovation employs advanced software that integrates AI and computer image processing to evaluate the quality, weight, and packaging status of ramen. Cameras installed on the production line analyze hundreds of thousands of product images using AI artificial neural networks to identify defects.

The domestic food industry is accelerating the adoption of AI technology, both locally and internationally, in a bid to enhance production efficiency and reduce costs, thereby boosting operating margins. Industry leaders are advocating for the widespread implementation of AI across various business facets, with some analysts predicting significant impacts on the food sector.

On October 13, industry sources revealed that Pulmuone intends to roll out an AI smart process system to its tofu factories in the United States, China, and Japan, alongside its Korean operations. Since the beginning of 2023, Pulmuone has been gathering real-time data on tofu production from 12 factories in Korea, 2 in the U.S., and 9 suppliers. The goal is to leverage AI technology, trained on extensive data accumulated over three years, to enhance both the quality and productivity of tofu production.

“AI will detect signs of facility abnormalities or predict changes in quality,” remarked a Pulmuone representative. “It will help improve quality by recommending optimal operating conditions based on process and raw material characteristics.”

Meanwhile, SPC Group‘s affiliate, Paris Croissant, has been utilizing AI dough-splitting solutions in its Seongnam bread factory since last year. Given the variable nature of dough due to fermentation, employees previously needed to manually manage the equipment to ensure even portions. The introduction of AI has markedly improved the accuracy of dough division, enhancing overall bread production efficiency.

SPC Group is also contemplating the expansion of this AI solution to other facilities by year-end. Additionally, the company is preparing to initiate construction of a “new safety smart factory” in Eumseong-gun, Chungcheongbuk-do, with plans to invest 300 billion won in a state-of-the-art bread factory featuring AI, automated robots, and Internet of Things (IoT) sensors. An official from SPC Group emphasized, “The goal is to start construction by the end of this year and complete it by 2028,” adding, “We aim to maximize production efficiency and safety.”

Ottogi is also rapidly adopting AI technology. Since November of last year, the company has employed AI for pilot production in new product launches, resulting in a 38% reduction in the time required to bring new products to market. The pilot production process is essential for assessing hygiene and product uniformity. Moreover, AI is now used to inspect expiration date markings on packaging, alleviating some of the manual workload for employees. An Ottogi representative stated, “A technology that checks the status of raw material costs, such as electricity and fuel, with AI and minimizes waste is also being applied.”

In addition, Dongwon F&B has implemented an AI X-ray inspection system for canned tuna at its Changwon plant in South Gyeongsang Province, effectively identifying fine bones that might evade even seasoned workers. This enhancement has led to a reduction in consumer dissatisfaction rates by over 20%.

Looking ahead, CJ CheilJedang plans to introduce additional AI quality inspection systems in factories located in Incheon and Yeongdeungpo starting in 2024, following the implementation of similar systems in Busan this year. These AI X-ray facilities will be positioned on conveyor belts to inspect products for foreign substances.

The food industry anticipates a rapid increase in the number of companies adopting AI technologies, suggesting a transformative shift in operational practices and quality assurance methods across the sector.

See also Mapúa University Launches First Bachelor’s in AI Engineering, Exceeding Enrollment Targets

Mapúa University Launches First Bachelor’s in AI Engineering, Exceeding Enrollment Targets Meta Announces Gigawatt-Scale AI Infrastructure Initiative, Aims for $600 Billion Investment

Meta Announces Gigawatt-Scale AI Infrastructure Initiative, Aims for $600 Billion Investment Nvidia Confirms No Upfront Payment Required for H200 AI Chips Amid Trade Concerns

Nvidia Confirms No Upfront Payment Required for H200 AI Chips Amid Trade Concerns Arcfield Unveils Intelligent MBSE, Enhancing Federal Engineering with AI Integration

Arcfield Unveils Intelligent MBSE, Enhancing Federal Engineering with AI Integration Nvidia, AMD, Broadcom Set to Triple Valuation in AI Infrastructure by 2030

Nvidia, AMD, Broadcom Set to Triple Valuation in AI Infrastructure by 2030