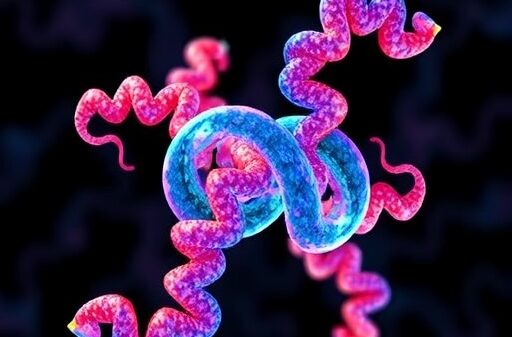

Researchers from the Institute of Biochemistry at Graz University of Technology (TU Graz), led by Gustav Oberdorfer, have unveiled a new technique for designing customized enzymes, a breakthrough with significant implications for industry, medicine, and environmental protection. Published in the journal Nature, the study introduces a method termed Riff-Diff (Rotamer Inverted Fragment Finder–Diffusion), which allows the precise construction of protein structures tailored around specific active centers, thus enhancing enzyme activity and stability.

This innovative approach diverges sharply from traditional methods that rely on searching existing databases for suitable protein structures. “Instead of putting the cart before the horse and searching databases to see which structure matches an active centre, we can now design enzymes for chemical reactions efficiently and precisely from scratch using a one-shot process,” said Oberdorfer. The lead author of the study, Markus Braun, emphasized that the newly created enzymes are highly efficient biocatalysts, demonstrating the potential for industrial applications due to their enhanced stability. This advancement significantly reduces the time and resources previously required for enzyme design, making it more accessible to the broader biotechnology community.

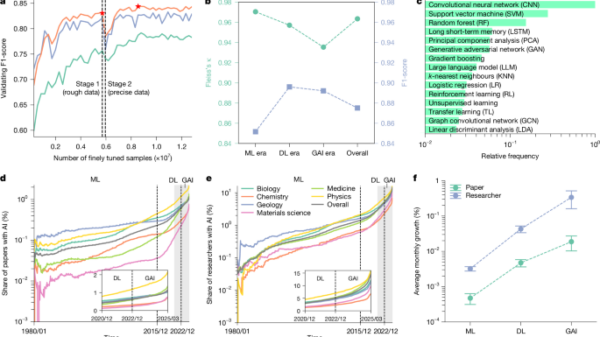

The development is underpinned by advances in machine learning, which enable the design of complex protein structures that were not possible with earlier techniques. Riff-Diff integrates several generative machine learning models with atomistic modeling. Initially, structural motifs of proteins are arranged around an active center, followed by the use of a generative AI model called RFdiffusion to create the complete protein structure. The researchers further refine this scaffold incrementally, achieving precision at the angstrom level—1 angstrom corresponds to 0.1 nanometers—validated by high-resolution experimental protein structures.

The method’s effectiveness has been confirmed through extensive laboratory testing, successfully generating active enzymes from 35 different sequences. These new catalysts demonstrated significantly faster reactions than previous computer-aided designs and maintained their functional shape at elevated temperatures, withstanding heat up to 90 degrees Celsius. This thermal stability is particularly critical for their prospective use in industrial settings.

“Although nature itself produces a large number of enzymes through evolution, this takes time. With our approach, we can massively accelerate this process and thus contribute to making industrial processes more sustainable, developing targeted enzyme therapies and keeping the environment cleaner,” said Adrian Tripp, another lead author from the Institute of Biochemistry at TU Graz.

This achievement also highlights the importance of interdisciplinary collaboration. Mélanie Hall from the Institute of Chemistry at the University of Graz remarked on the benefits of integrating diverse expertise from protein science, biotechnology, and organic chemistry. “The integration of different areas of expertise at the interface of protein science, biotechnology and organic chemistry shows how crucial interdisciplinary approaches are for the advancement of modern biocatalysis,” Hall stated.

The implications of this research are broad, potentially leading to enhanced methods for creating biocatalysts that could revolutionize industrial processes and pave the way for new therapies in medicine. As the technology matures, it may play a key role in efforts to develop more sustainable chemical manufacturing practices and targeted enzyme therapies, contributing to a cleaner environment and more efficient industrial applications.

As the biotechnology sector continues to evolve, the capabilities provided by Riff-Diff could serve as a catalyst for innovation, enabling researchers and industries to address pressing challenges in a more efficient and environmentally friendly manner. For further details, the complete study can be found in the Nature journal under the title “Computational enzyme design by catalytic motif scaffolding” (DOI: 10.1038/s41586-025-09747-9).

See also AI Transforms Mobility Operations: Proven Strategies from EY and Novartis to Drive Efficiency

AI Transforms Mobility Operations: Proven Strategies from EY and Novartis to Drive Efficiency Germany”s National Team Prepares for World Cup Qualifiers with Disco Atmosphere

Germany”s National Team Prepares for World Cup Qualifiers with Disco Atmosphere 95% of AI Projects Fail in Companies According to MIT

95% of AI Projects Fail in Companies According to MIT AI in Food & Beverages Market to Surge from $11.08B to $263.80B by 2032

AI in Food & Beverages Market to Surge from $11.08B to $263.80B by 2032 Satya Nadella Supports OpenAI’s $100B Revenue Goal, Highlights AI Funding Needs

Satya Nadella Supports OpenAI’s $100B Revenue Goal, Highlights AI Funding Needs